Unlocking the Key to 730W Mass Production: The Game-Changing Role of High-Mobility Target Materials

On October 15, 2024, Risen Energy announced the launch of its upgraded HJT module, the Hyper-ion Pro, featuring an impressive mass production power output of 730Wp+. Unlike lab records or efficiency benchmark often highlighted in the industry, this announcement emphasizes “mass production power”. Achieving a mass production power of over 730Wp relies on advancements in cell efficiency and the optimized application of new materials and encapsulation technologies. Among these, the most crucial progress are the development and application of high-mobility target materials, full-open stencil screen printing, and UV down-conversion encapsulation film technologies. This article delves into the crucial role of high-mobility target material in achieving 730Wp power output.

What Are Target Materials?

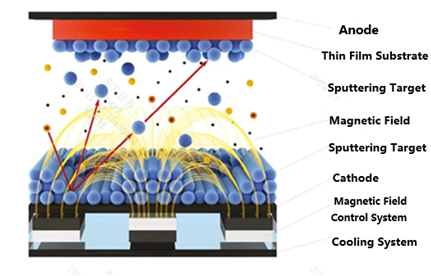

Target material, also known as sputtering target material, is a fundamental component in materials science and semiconductor manufacturing. It is used in deposition process, where high-speed ion beam bombard target materials, causing the atoms to sputter out and deposit onto a substrate, forming a thin film (Figure 1). The selection of the target material have a decisive influence on the performance of the deposited film.

Figure 1. Film deposition via target material sputtering

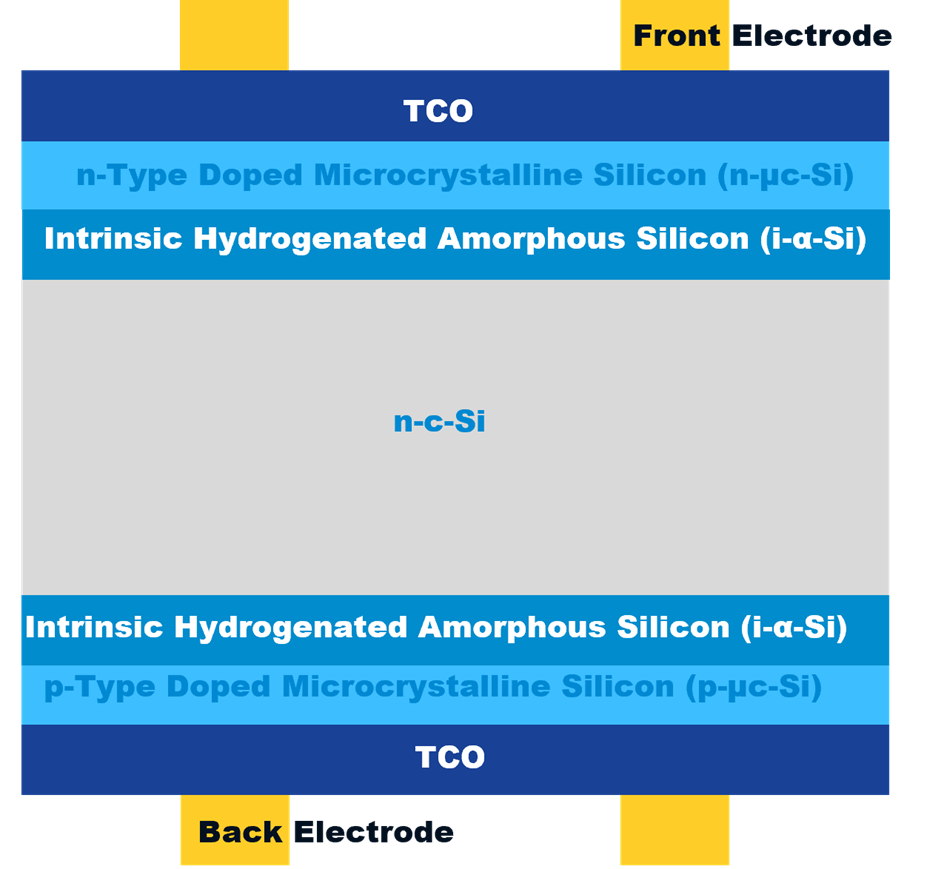

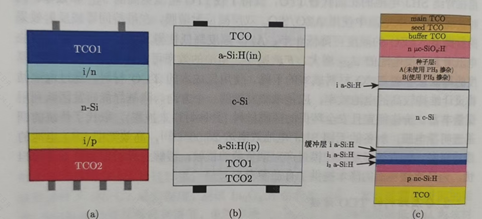

The outermost layer of HJT solar cell is TCO (Transparent Conductive Oxide) film. In HJT solar cell production, the TCO film is deposited using target material (Figure 2). The selection of material and process for producing TCO film is critical to achieving high efficiency in HJT solar cells.

Figure 2. Structure of an HJT cell

Why Use TCO?

Compared to the traditional thermal-diffused crystalline silicon solar cells (including BSF, PERC, and TOPCon), a significant difference in HJT solar cells is the low conductivity of the emitter (i.e. α-Si: H).

Due to this characteristic, collecting current from the emitter layer solely through metal gridlines on the front and back surfaces of solar cells is insufficient. Thus, an alternative electrical contact solution is required, and the use of a TCO film, which is both conductive and transparent, serves this purpose effectively.

As a transparent conductive oxide film, TCO film has both conductivity and transparency and can be used in many occasions, especially in the field of optoelectronic devices. In HJT solar cells, the TCO film is applied on the outermost layer of the cell structure. It can support conductivity, light transmittance, and anti-reflection (Figure 2).

Why High Mobility Needed?

Given the dual role of TCO in supporting conductivity and light transmittance for HJT solar cells, TCO film must possess appropriate electrical and optical properties, which are interdependent and must be simultaneously optimized to maximize cell efficiency. Therefore, the TCO film used in HJT cells require the following properties:

1.Low resistivity;

2.High transmittance;

3.Low-temperature growth capability.

Currently, most research on improving HJT efficiency focuses on reducing the resistivity of the TCO film.

But how do low resistivity and high mobility correlate?

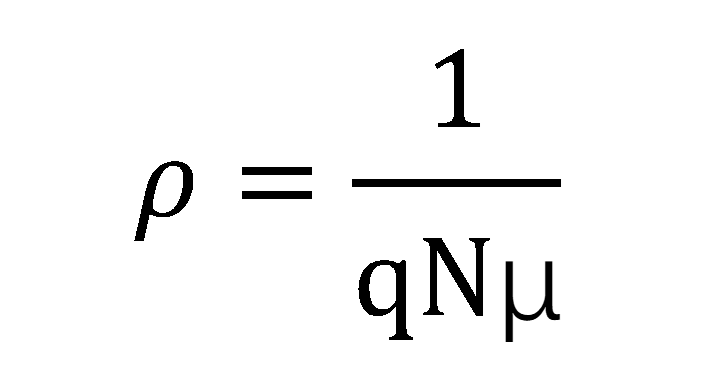

The relationship between resistivity, free carrier concentration and mobility can be described by the following formula:

--------------------------- Formula 1

--------------------------- Formula 1

Where ρ represents resistivity, q represents electron charge, N is the free carrier concentration, and μ is the carrier mobility. This formula reveals that to achieve low resistivity (ρ), either increasing the free carrier concentration (N) or enhancing carrier mobility (μ) is feasible. However, increasing carrier concentration excessively can lead to higher absorption of visible light within the TCO film, reducing transmittance and thus adversely affecting cell efficiency. Therefore, researchers and engineers primarily focus on optimizing the carrier mobility of the TCO film rather than maximizing its carrier concentration. Consequently, reducing resistivity is not achieved solely through increasing carrier concentration but rather through maximizing carrier mobility.

From another perspective, solar cells achieve photovoltaic conversion by absorbing sunlight, where greater light absorption means higher energy conversion efficiency. Within the solar spectrum (300–2500nm), visible light (400–760nm) accounts for 43% of the energy, ultraviolet (300–400nm) contributes 5%, while near-infrared (760–2500nm) contributes 52%. Conventional TCO films have high infrared reflectance, limiting the effective utilization of long-wavelength sunlight. Improving TCO film transmittance in the infrared range can thus enhance solar cell efficiency. To achieve this, the carrier concentration must be reduced to improve light transmittance, but this may increase TCO resistivity according to Formula 1. Thus, TCO material and process development focuses on reducing carrier concentration while maximizing mobility. This allows TCO to maintain good conductivity while achieving high transmittance across the visible to near-infrared spectrum, thereby increasing HJT cell conversion efficiency.

Risen Energy’s R&D and Application of High-Mobility Target Materials in HJT Hyper-ion Solar Cells

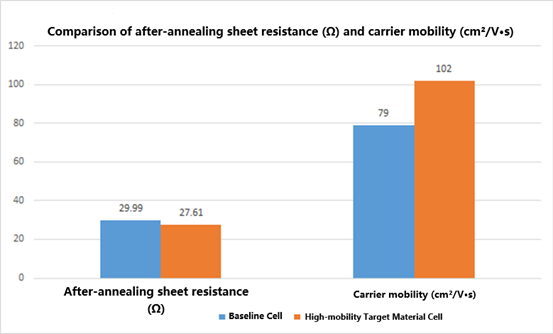

1.Significant Reduction in TCO Sheet Resistance and Enhancement of Carrier Mobility

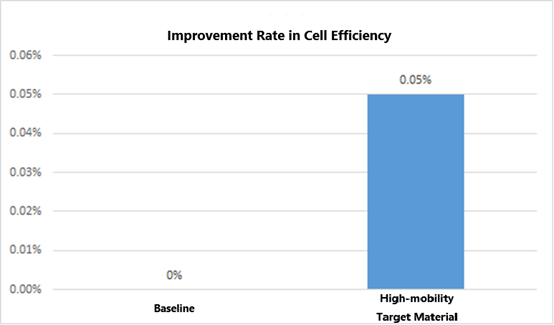

During the development of high-mobility target materials, by precisely controlling material composition and process parameters, Risen Energy increased carrier mobility up to 29.11% (Figure 3). This advancement increased the photoelectric conversion efficiency of high-efficiency HJT solar cells by 0.05%. By reducing carrier concentration without compromising electrical properties, light absorption in the film is minimized, allowing more light energy to be converted into electricity and improving conversion efficiency (Figure 4).

Figure 3. Changes in sheet resistance and carrier concentration

Figure 4. Improvement rate in cell efficiency

2.Increased Near-Infrared Transmittance and Enhanced EQE Performance

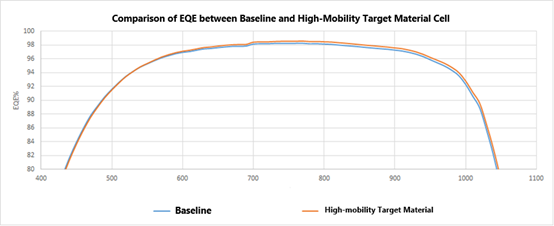

HJT solar cells incorporating high-mobility target materials demonstrate superior External Quantum Efficiency (EQE). The EQE performance is higher across the visible to near-infrared range compared to baseline and slightly lower in ultraviolet range, effectively boosting overall solar cell efficiency.

Figure 5. Changes in EQE performance

Outlook for TCO Film Technology in HJT Solar Cells

Scientists have mapped out a clear roadmap for optimizing TCO films, focusing on achieving low-cost scalability in mass production. Some technical solutions have been implemented in commercial HJT production, while others are still in development.

Initially, identical materials and structures were used for the TCO films on both sides of HJT solar cells. However, as technology has progressed, particularly in the mainstream rear-junction HJT solar cells, different material compositions can now be used for the front and rear TCO films to fulfill distinct performance requirements,. Additionally, traditional single-layer TCO films often struggle to achieve optimal optical, electrical, and interfacial contact properties. Thus, dual-layer or even multi-layer TCO structures have emerged as effective strategies of further improving HJT solar cell efficiency (Figure 6), and these are now being applied in commercial mass production.

Figure 6. Schematic of multi-layer TCO film in HJT cells

Source: “Perovskite/Si Heterojunction Tandem Solar Cells” (Wenzhong Shen)

Risen Energy’s dedicated research and innovation in HJT cell technology, particularly in developing and applying high-mobility target materials, has contributed significantly to the company’s growth and the advancement of the global photovoltaic industry. Moving forward, Risen Energy will continue to embrace innovation, lead technological advancements in industry and support the widespread adoption of renewable energy, building a sustainable and green future.