Unlocking the Key to 730W Mass Production: How Full-Open Stencil Screen Printing Boosts Efficiency?

Amid rapid advancements in the global photovoltaic industry, Risen Energy has consistently led the sector with its years of expertise and innovation in the heterojunction (HJT) cell technology. On October 15, Risen announced the mass production of its groundbreaking 730Wp+ Hyper-ion Pro series, setting a new industry benchmark for the highest output of a single solar module. Behind this achievement are advancements in cell efficiency and the optimized application of new materials and encapsulation technologies. A crucial innovation behind this success is the full-open stencil screen printing technology, which we'll dive into in this article.

In solar cells, electrodes are printed on both the front and back sides to form a close ohmic contact with the PN junction. The electrode on the light-receiving front side is called the top electrode, usually designed in gridlines to collect the photogenerated current. And the electrode on the backside is known as back electrode. While various methods like vacuum deposition, electroplating, and screen printing can be used to create these electrodes, screen printing remains the most widely adopted and cost-effective technique in the photovoltaic industry due to its efficiency in production.

To enhance the performance of heterojunction solar cells from the perspective of electrode manufacturing, improvements are generally made in three aspects:

Minimizing gridline width to reduce shading and thus increase current density of the solar cells.

Using advanced metallization pastes to improve the fill factor of the solar cells.

Constructing gridlines with higher aspect ratio to enhance solar cell's fill factor.

The development and introduction of full-open stencil screen printing primarily aim to achieve efficiency improvements and cost reductions in HJT solar cells by addressing the first and third points mentioned above.

Full-Open Stencil Screen Printing Technology: A Perfect Combination of Efficiency and Precision

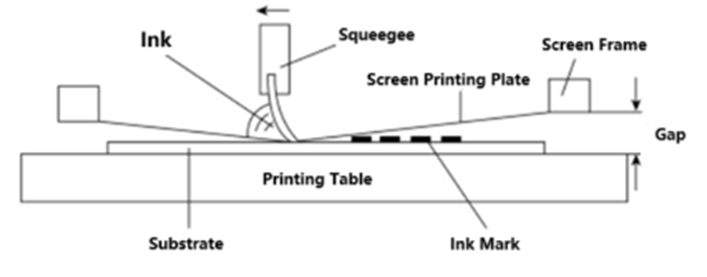

Screen printing is a technology that uses a mesh pattern where some mesh holes allows paste to pass through, while others do not. During printing, paste is poured on one end of the screen, and a squeegee applies pressure while moving to the other end, forcing the paste through the mesh openings onto the substrate, as illustrated in Figure 1.

Figure 1. Schematic of screen printing

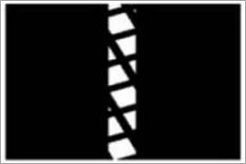

In traditional screen printing, mesh screen are woven from stainless steel (tungsten) wire in varying mesh sizes, with a PI film coated in photosensitive adhesive. There are two main types of mesh screen: conventional mesh screen with a 22.5° angle and knotless mesh with 0° and 90° angles, as shown in Figure 2. Throughout the evolution of screen printing technology, in order to improve the shape of the gridlines, the industry has gradually transitioned from conventional mesh screen to knotless mesh screen.

(a) Conventional (b) knotless

Figure 2. Comparison between conventional (a) and knotless (b) mesh sceen

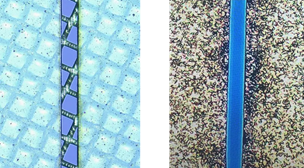

The full-open stencil screen printing technology employs a specially designed stencil that achieves 100% opening rate, meaning no mesh fibers obstructs the opening area, thus enabling higher ink transmittance, as shown in Figure 3. This advancement offers multiple significant advantages for solar cell manufacturing ans show great potential especially in the metallization process of heterojunction cells.

(a) conventional (b) full-open stencil

Figure 3. Comparison between conventional (a) and full-open stencil (b)

1.High-Precision Printing to Improve Photovoltaic Conversion Efficiency

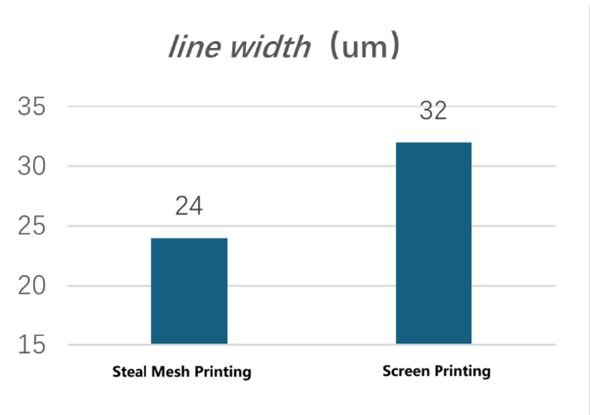

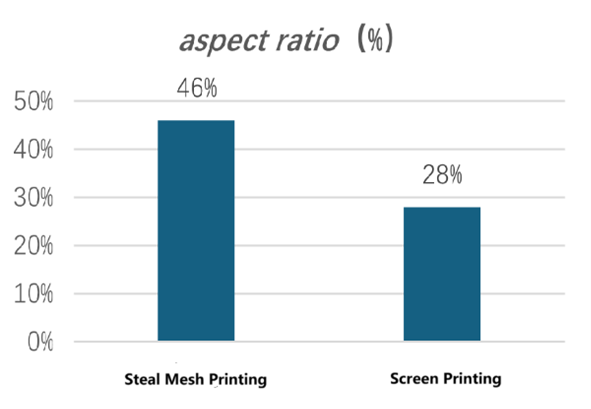

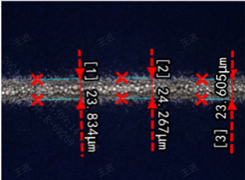

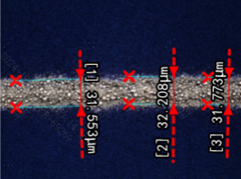

The full-open stencil screen printing has achieved fine gridline width of less than 25µm, with further optimizations expected to reduce the width to below 20µm, as shown in Figure 4. Thinner gridlines significantly reduce the shading on the cell surface, thus increasing the active light-receiving area, effectively enhancing photovoltaic conversion efficiency. By designing different gridline width and counts that correlate with shading and resistance, Risen Energy tested to find the optimal combination, which improved short-circuit current (Isc) and fill factor (FF), leading to a cell efficiency increase of 0.12%.

(a) Comparison of gridline width (b) Comparison of aspect ratio

Figure 4. Difference in gridline width and aspect ratio between stencil screen printing and screen printing

2.Reducing Paste Consumption and Lowering Metallization Costs

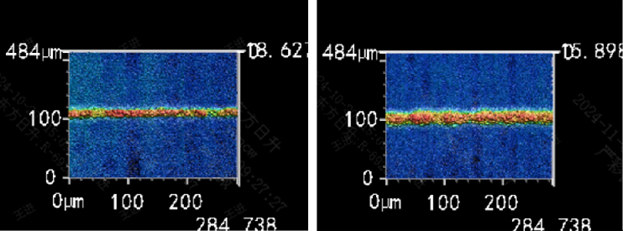

The full-open stencil mesh screen increases paste transmittance, reducing paste consumption by up 20%, as illustrated in Figure 5. Given the high cost of paste in solar cell manufacturing, stencil screen printing can effectively lower metallization costs and make production more economical.

(a) Stencil Screen Printing Effect (b) Screen Printing Effect

(c) Stencil Screen Line Width (d) Screen Line Width

Figure 5. Comparison of Printing Effects and Line Width between Stencil Screen Printing and Screen Printing

3.Improved Printing Quality and Reduced Resistance

The gridlines produced by full-open stencil screen printing are uniform and flat, with less variability in height compared to traditional screen printing. This high-quality printing reduces gridline resistance, improving the cell's fill factor (FF). A higher fill factor ensures more stable power output in practical applications, further enhancing overall cell performance.

4.Extended Printing Lifespan and Increased Production Efficiency

Constructed from puncture-resistant and wear-resistant steel, full-open stencil screen has a substantially longer lifespan than traditional mesh screen—by at least double. This reduces mesh replacement frequency, maintenance costs, and ensures stable production efficiency. For large-scale photovoltaic manufacturers, this advantage not only improves production stability but also reduces long-term operational costs.

Risen Energy's R&D Advantage and the Perfect Integration with Full-Open Stencil Screen Printing

Risen Energy's extensive technical accumulation and R&D investments in heterojunction cells provide a solid foundation for applying and optimizing full-open stencil screen printing technology. The company’s experienced R&D team focuses on materials, processes, and equipment optimizations to ensure each new technology achieves optimal performance in production.

By applying full-open stencil screen printing to heterojunction cell production, Risen Energy has successfully achieved both efficiency and cost optimization. This breakthrough has been crucial to achieving mass production of the 730Wp+ Hyper-ion Pro series. Moving forward, Risen Energy will continue to drive photovoltaic innovation, contributing to the sustainable growth of the global renewable energy sector.