Mastering UV Down-conversion Encapsulation Film - Risen’s New Milestone in HJT Hyper-ion Technology

The better the passivation effect of a solar cell, the more susceptible it is to UV light.

Achieving higher solar cell conversion efficiency requires effective surface passivation. High bulk and surface recombination rates can limit the open-circuit voltage (Voc) and reduce the fill factor (FF) of the solar cells. Therefore, applying high-quality surface passivation layers to suppress surface recombination is a prerequisite for achieving high-efficiency solar cells.

For solar cells, effective surface passivation is reflected microscopically by reduced defect state density and decreased interface recombination, while macroscopically it is evidenced by an increase in minority carrier lifetime and a rise in Voc. Throughout the development of solar cell technologies, from early BSF (Back Surface Field) to PERC (Passivated Emitter Rear Contact), and now to n-type TOPCon (Tunnel Oxide Passivated Contact) and HJT (Heterojunction) technologies, it is evident that the history of solar cell technology is the advancements of passivation materials and processes. Each cell technology innovation and efficiency improvement is closely tied to the optimization of passivation materials and technologies. Early BSF solar cells were passivated with TiO2 and later shifted to SiNx passivation, but only for the front side. PERC solar cells, in contrast, applied backside passivation using Al2O3 and SiNx. However, metallization and the laser ablation process led to partial passivation instead of full-area passivation. TOPCon solar cells, in mass production nowadays, utilize a rear-side passivated contact structures with SiO₂ and polysilicon. HJT solar cells, incorporating the advantages of previous technologies, adopt bifacial full-area passivation with amorphous silicon, achieving the best passivation effects and the highest Voc. Among current mainstream solar cell technologies, HJT solar cells offer the highest mass-produced Voc, exceeding 753mV in average, making them the most effective in terms of passivation among all single-junction solar cells.

Photovoltaic cell passivation layers reduce surface defects by forming Si-H bonds, which saturate the dangling bonds on the semiconductor surface, thus lowering the recombination losses of photo-generated carriers. This enhances photoelectric conversion efficiency and extends the cell's lifespan. However, Si-H bonds are easily broken by UV exposure, leading to reduced passivation and, consequently, decreased conversion efficiency. This phenomenon, known as UV-Induced Degradation (UVID), is especially pronounced in high-efficiency n-type solar cells where superior passivation is achieved. Much like a pristine white porcelain shows dirt more visibly than a gray one, the better the passivation, the more pronounced the impact of UV exposure.

No tools, no job – Mitigating UV Effects with Encapsulation Films

As the most passivation-effective and efficient single-junction technology, HJT solar cells are more susceptible to the effects of UV light on the passivation layer than other technologies. To mitigate and eliminate this impact, scientists and engineers in the photovoltaic industry generally employ two solutions. The first one is to use high-cut-off encapsulation film, which contains UV cut-off agents that reduce the UV transmittance in the 280–380 nm range to about 2%–15%, effectively minimizing the amount of UV reaching the solar cell surface. However, this approach also decreases the incident light energy, leading to lower CTM and more power loss.

The second solution, UV down-conversion films, has gradually gained attention. These films can convert certain wavelengths of incident light into others by replacing UV cut-off agents with UV down-conversion agents in the encapsulation films. Risen Energy's research team has developed UV conversion films that reduce UV transmittance in the 280–380 nm range to below 2% while maintaining high visible light transmittance. More importantly, the films convert UV light into harmless blue light. This dual-purpose approach not only protects the cells from UV damage but also harness UV energy to boost module power, improving both reliability and power efficiency by more than 1% compared to high cut-off films.

As the saying goes, "No tools, no job," the real mastery lies in knowing how to use the tool effectively. The UV down-conversion film is akin to a “diamond tool”, it not only effectively reduces UV damage to high-efficiency solar cells but also enhances module power output. Yet, mastering the use of this tool is key to unlocking its full potential.

Mastery in UV Down-Conversion Encapsulation Film Application

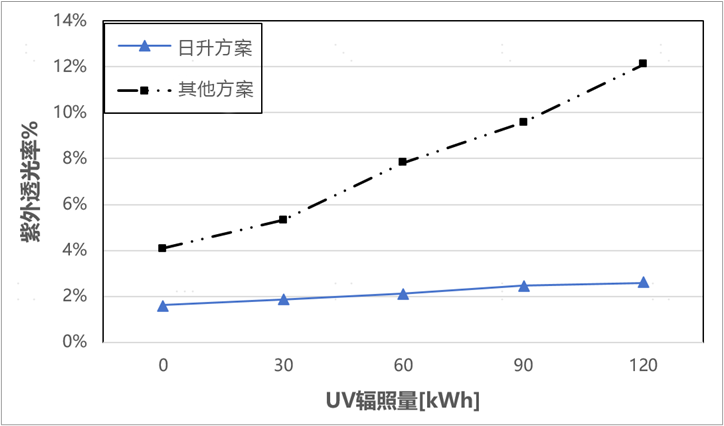

In practical application research and development, Risen Energy researchers found that the concentration of light down-conversion agent plays a crucial role in encapsulation films stability. If the concentration falls below a certain threshold, it degrades over time under cumulative UV exposure, causing UV transmittance to increase. After extensive testing and development, Risen Energy, in collaboration with suppliers, has developed a highly stable UV down-conversion encapsulant (as shown in Figure 1). After stringent UV120 testing, the encapsulant maintains consistently low UV transmittance, demonstrating high stability.

Figure.1 UV transmittance variation of the encapsulation film with cumulative UV exposure

Beyond the technical requirements for the encapsulation film itself, configuring the optimal encapsulation BOM (Bill of Materials) for it is also key to leveraging its full potential. As naturally bifacial solar cell with bifaciality exceeding 95%, HJT solar cells can still reach bifaciality over 85% when encapsulated in modules. In power plants, the high bifacial factor of HJT modules is a key contributor to higher power generation. Considering that the rear side also generates power, it's necessary to address the UV impact on the module's rear side when using UV down-conversion film on the front. Through extensive testing and innovation, Risen Energy researchers have developed a breakthrough solution, creating an encapsulation film that effectively protects the rear side of HJT solar cells.

The successful development and application of Risen Energy's UV down-conversion solution has reduced power losses from encapsulation with high cut-off encapsulant, increasing HJT module power output by about 10W. Furthermore, it offers unique advantages in module reliability, significantly minimizing UV effects on HJT solar cells and ensuring long-term stability in outdoor environments with lower degradation. By redefining and optimizing the use of UV down-conversion materials, Risen Energy's scientists and engineers have made UV down-conversion encapsulation film technology a stable and efficient application solution, upgrading Risen’s HJT products from "Hyper-ion 1.0" to "Hyper-ion 2.0."

Forging Ahead in the Green Energy Transition

As a global leader in photovoltaic products and solutions, Risen Energy has long been committed to the R&D and mass production of HJT technology and products. HJT Hyper-ion modules integrate years of R&D achievements, and is the first in the industry to achieve 0BB mass production, large-scale application of ultra-thin solar cell, metallization with less than 6mg/W silver consumption, and low-stress Hyper-link interconnection technology, which plays an industry-leading role in the mass production of HJT technology. In the development of this UV down-conversion solution, Risen Energy redefined UV down-conversion materials and innovated the application methodology, making UV down-conversion technology a stable and efficient solution. We believe this will mark yet another milestone for the entire photovoltaic industry.

Amid the backdrop of the "dual carbon" goals and the global transition to green energy, Risen Energy embraces its social responsibility and actively explores the development and innovation of green energy technologies. With profound technical expertise and innovative spirit, they continue to drive the industry's progress. As the value of heterojunction (HJT) technology becomes increasingly evident, and with ongoing breakthroughs in both HJT and corresponding encapsulation technologies, these high-efficiency, low-carbon HJT products are poised to make significant contributions to the global energy transition and environmental protection, while bringing new insights and strength to the sustainable development of the global photovoltaic industry.